The distribution of the various components, cost and weight of the battery system is actually an interesting question. Looking at it with a small battery pack (20kwh), a large battery pack (60kwh) and a PHEV battery pack (8-10kwh) and a HEV package, the cost of the electrical system and battery management system (BMS) is a set of one package, so these two are actually diluted with the proportion of capacity kwh.

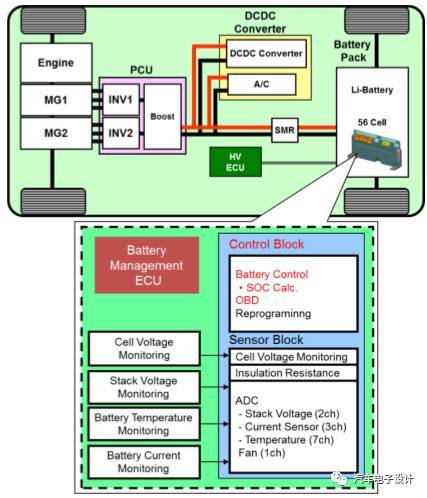

Reading Denso about the BMS system of HEV from SAE . It is more meaningful about some aspects of design. Let's take a look at some of the contents.

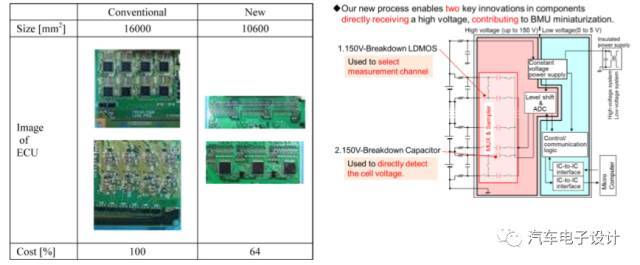

To put it simply, this product is implemented around the cost reduction of HEV Pack for lithium batteries. The previous generation of lithium battery BMS was taken over and the channel of each ASIC was further increased.

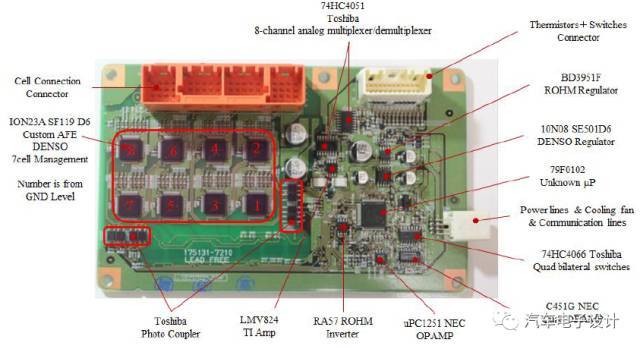

Last generation BMS

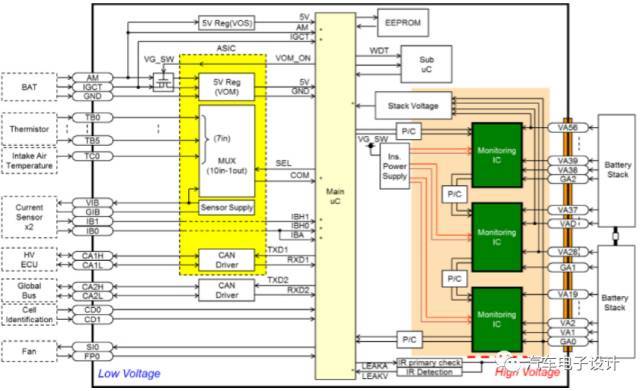

This generation of BMS

Observing the change of AFE, the reduction of chip makes the cost drop by 36%. The core is that Denso has semiconductor technology, which makes the ASIC's withstand voltage higher, and achieves 150V withstand voltage, and the whole power supply is reduced.

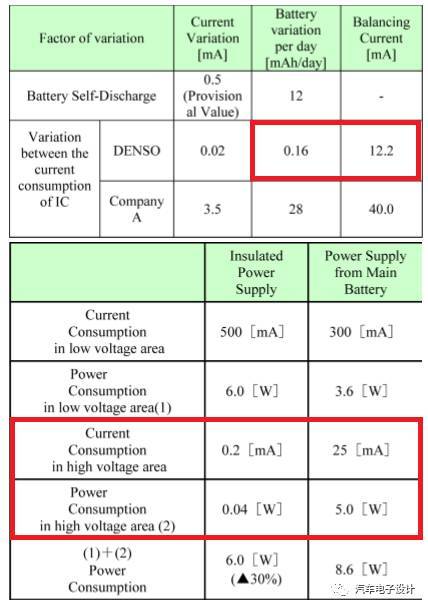

There is an interesting and interesting part here. The self-discharge of small-capacity lithium batteries and the difference in self-discharge caused by AFE leakage and working current difference, the battery does not feel that when the battery is small, the difference in the entire path will lead to follow-up The change, at least the passively balanced current is also pulled down. Stack is also the difference between the power-receiving modules, and the difference is made smaller by the high-pressure combined mode.

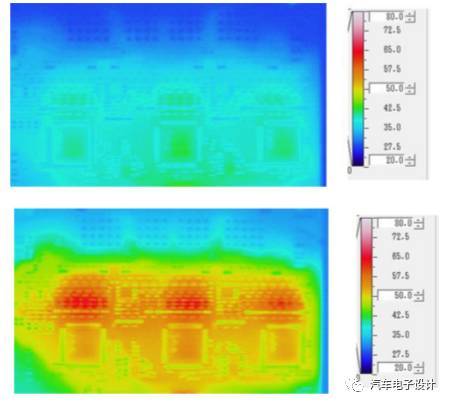

The choice of shell materials for BMU and BMS is in fact that plastic and metal shells need to be considered for waterproofing (especially for liquid cooling systems), for work and balanced heating, and for EMC (ESD problems in modules and Pack assemblies).

I personally think that in the future, BMS systems need to integrate multiple capabilities and solve and optimize them from a chip perspective. Especially under the impetus of HEV, in fact, a single set of BMS and BDU has been ground to a very low cost (proportion of the ratio). With the amount of EV, because the cost of electronic and electrical systems is relatively low, in fact, we pay attention to the price of batteries. In the future, it will be done on a large scale. If the money is not saved by one point, it will be at least one piece.

summary:

Companies that do 48V and do HEV will definitely impose strict challenges on the cost of BMS and BDU, and even DCDC electronic and electrical systems. Here, making money is calculated in blocks, which is actually the normal state in the car. If we look at the booming parts of new energy vehicles in recent years, it is actually not normal. Money can not be ruined, it is to be earned a little bit, and the brothers who do BMS must adapt to this change in price trends in advance. The price of the BOM will be more cruel than the competition we imagined.