In 1995, the pouch cell surprised the battery world with a radical new design. Rather than using a metallic cylinder

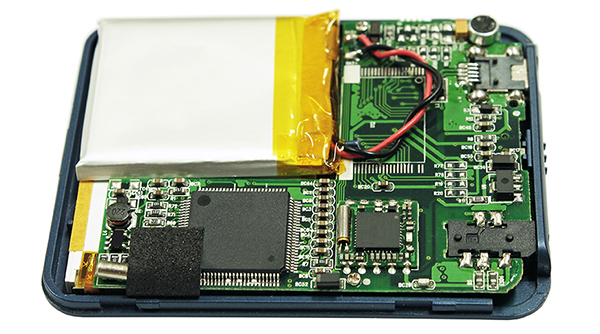

The pouch cell.

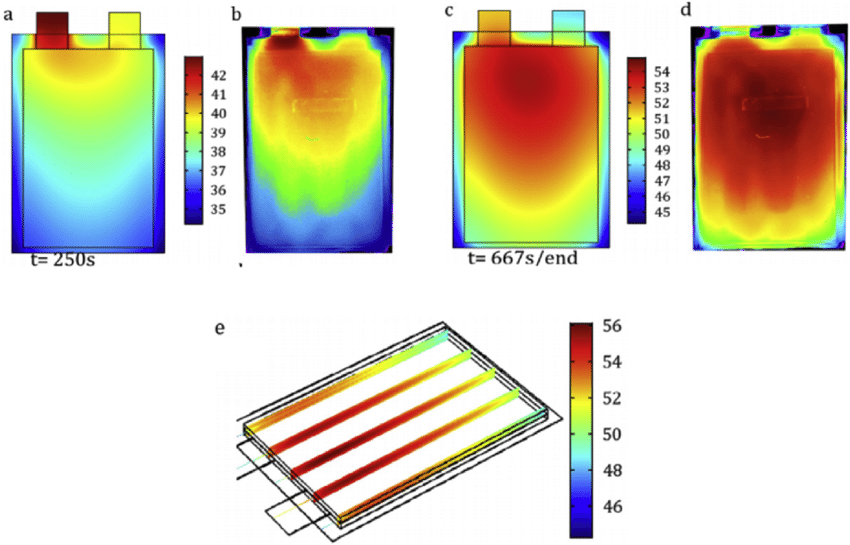

The pouch cell offers a simple, flexible and lightweight solution to battery design. Some stack pressure is recommended but allowance for swelling must be made. The pouch cells can deliver high load currents but it performs best under light loading conditions and with moderate charging.

Extreme swelling is a concern. Users of pouch packs have reported up to 3 percent swelling incidents on a poor batch run. The pressure created can crack the battery cover, and in some cases, break the display and electronic circuit boards. Discontinue using an inflated battery and do not puncture the bloating cell in close proximity to heat or fire. The escaping gases can ignite.

The prismatic metallic case has improved packaging density but can be more expensive to manufacture, is less efficient in thermal management and may have a shorter cycle life.

The prismatic pouch pack is light and cost-effective to manufacture. Exposure to high humidity and hot temperature can shorten service life.